As an efficient acoustic application equipment, LRAD (Long Range Acoustic Device) has been widely used in various fields such as emergency communications, safety prevention and control, and bird hazard management. Different scenarios have significantly different requirements for the performance, functions, and adaptability of LRAD acoustic systems. If the selection is improper, it will not only fail to exert the core value of the equipment but also cause resource waste or fail to meet actual needs. As an enterprise focusing on acoustic technology for 18 years, RIBRI, relying on the technical accumulation of directional and omnidirectional LRAD acoustic systems and full - chain customization capabilities, provides users with diversified choices. This guide will help users accurately select the LRAD acoustic system that suits their own needs from four core dimensions: scenario matching, performance screening, customization requirements, and quality verification.

Step 1: Clarify the Usage Scenario and Lock the System Type

The primary prerequisite for selecting an LRAD acoustic system is to match the specific usage scenario. The environmental characteristics and core needs of different scenarios directly determine the system type (directional or omnidirectional) and functional configuration. RIBRI's LRAD acoustic systems are divided into two major series: directional and omnidirectional, which target the two types of needs of "precise coverage" and "comprehensive protection" respectively. Users need to first clarify the core demands of their own scenarios to avoid blind selection.

In emergency communication scenarios, if the need is for highway accident early warning and precise announcement in disaster rescue, priority should be given to the directional LRAD acoustic system. Such scenarios require precise transmission of information to specific areas (such as around accident vehicles and the location of trapped people) to avoid sound wave diffusion interfering with unrelated areas. For example, in foggy weather on the highway, the directional system can focus the sound beam to penetrate the vehicle window and deliver deceleration warnings to drivers in specific lanes within 500 meters. During the rescue of a collapsed building, the directional system can penetrate noise and dust to deliver danger - avoidance instructions to trapped people 1,000 meters away.

If the scenario is for large - scale early warning (such as airport bird hazard prevention and control and emergency broadcasting in large - scale events), the omnidirectional LRAD acoustic system is more suitable. Airports need 360 - degree coverage of the area around the runway, apron, and outer wetland. The omnidirectional system can form a "sound wave protection circle" with a radius of hundreds of meters to prevent birds from approaching. When a sudden safety incident occurs in a large sports stadium, the omnidirectional system can quickly deliver evacuation routes to the audience in the entire venue to ensure that the information covers all areas without dead ends. In addition, for outdoor harsh environments (such as heavy rain and sand dust), attention should be paid to the protection level of the system. Both RIBRI's omnidirectional and directional LRAD systems meet the IP66 protection standard and can meet the needs of all - weather outdoor use.

Step 2: Focus on Core Performance and Screen Key Parameters

After determining the system type, it is necessary to further screen the core performance parameters to ensure that the actual effect of the LRAD acoustic system can match the scenario needs. The key performance parameters of RIBRI LRAD acoustic systems include sound pressure level, coverage distance, frequency range, and response speed. These parameters directly determine the information transmission efficiency and environmental adaptability of the equipment, and users need to verify them one by one according to the scenario needs.

Sound pressure level and coverage distance are the core indicators to measure whether the LRAD system can "transmit far and be heard clearly". For emergency rescue and long - distance security scenarios, it is necessary to select a system with high sound pressure level and long coverage distance. RIBRI's directional LRAD system can have a sound pressure level of more than 138dB and an effective coverage distance of more than 1,000 meters at 70dB, which can meet the long - distance announcement needs of disaster rescue in remote areas. For community security and small - scale event broadcasting scenarios, a system with a sound pressure level of 80 - 100dB and a coverage distance of 200 - 500 meters is sufficient to avoid noise interference caused by excessive sound pressure level.

The frequency range determines the clarity of information transmission and the adaptation object of the LRAD system. For emergency broadcasting scenarios targeting human hearing, the frequency range of the system needs to cover 200Hz - 4kHz (the main frequency range of human voice). RIBRI LRAD system ensures that the voice command is clearly distinguishable by optimizing the sound wave output in this frequency band. For airport bird hazard prevention and control scenarios, it is necessary to select a system covering 2kHz - 20kHz. This frequency band can simulate the calls of bird natural enemies or high - frequency warning sounds to trigger the instinct of birds to avoid danger. In addition, attention should be paid to the response speed parameter - emergency scenarios require that the delay from the start of the system to the output of sound waves does not exceed 1 second. RIBRI LRAD system supports the quick wake - up function, which can realize instantaneous start through manual buttons or remote control terminals to meet the rapid response needs of emergency scenarios.

Step 3: Consider Customization Capabilities and Adapt to Scenario Details

Different users have personalized needs for scenarios, and the standardized LRAD system may not fully match the detailed requirements. In this case, priority should be given to brands with full - chain customization capabilities. Based on the concept of "technology - driven product diversification", RIBRI can adjust the functional modules, installation methods, and control interfaces of the LRAD system according to the details of the user's scenario to ensure that the equipment is seamlessly integrated with the existing system and maximize the use value.

The customization of functional modules can add or optimize functions according to the special needs of the scenario. For example, if the transportation department needs to connect the LRAD system with the highway monitoring platform, RIBRI can add a TCP/IP network interface to realize the data linkage between the monitoring system and the LRAD system - when the monitoring detects a road danger, it automatically triggers the LRAD system to play the early warning voice. If the airport needs to use the LRAD system in combination with the radar detection system, RIBRI can customize the radar data receiving module to enable the LRAD system to automatically adjust the sound beam angle and frequency according to the bird trajectory captured by the radar.

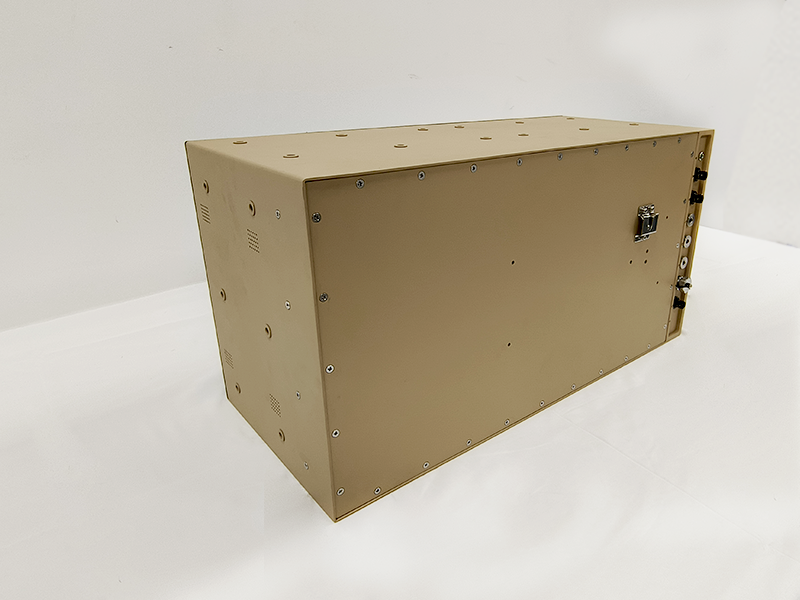

The customization of the installation method needs to adapt to the deployment environment of the scenario. For fixed scenarios (such as airport runways and factory walls), the LRAD system with wall - mounted or column - mounted installation can be selected. RIBRI provides customized installation brackets to ensure the stable fixation of the equipment. For mobile scenarios (such as emergency rescue vehicles and patrol boats), vehicle - mounted and ship - mounted systems should be selected. RIBRI can adjust the equipment size and fixing method according to the vehicle model and hull structure to ensure the stable operation of the equipment during driving or navigation. In addition, the customization of the control method can meet the operating habits of different users, supporting multiple methods such as button - type and remote terminal control, and adapting to different users such as emergency command centers and on - site staff.

Step 4: Verify Quality Certification and Ensure Long - term Reliability

LRAD acoustic systems are mostly used in key scenarios such as safety protection and emergency support, so the long - term reliability and compliance of the equipment are crucial. Users need to verify the brand's production strength, quality certification, and testing system to ensure that the selected LRAD system operates stably during long - term use and meets industry standards and environmental protection requirements.

Production strength and testing system are the basic guarantees of quality. RIBRI has a 2,600 - square - meter standardized production base in Tianjin, equipped with a semi - anechoic chamber certified by the national metrology institution. It can accurately test parameters such as the sound pressure level, directivity, and frequency response of the LRAD system to ensure that each equipment meets the performance standards. The production process, from the screening of core components to the assembly and debugging of the whole machine, undergoes more than 3 quality inspection procedures to avoid performance fluctuations caused by production errors. Users can verify the production and testing capabilities by inspecting the brand's production base or requesting test reports.

Quality certification and compliance are prerequisites for the safe use of equipment. RIBRI LRAD acoustic systems have all passed CE certification, complying with EU electrical safety and electromagnetic compatibility standards, and will not cause electromagnetic interference to surrounding facilities such as airport navigation equipment and hospital medical equipment. The IP66 protection certification ensures that the equipment does not enter water or accumulate dust in heavy rain and sand dust environments, making it suitable for long - term outdoor deployment. In addition, attention should be paid to environmental protection compliance - for bird hazard prevention and control and ecological protection area scenarios, the sound wave frequency and sound pressure level of the LRAD system need to comply with animal protection standards. RIBRI system optimizes the sound wave output to effectively repel birds without causing permanent harm to them, achieving a balance between safety and environmental protection.

Choosing the right LRAD acoustic system requires considering scenario matching, performance parameters, customization capabilities, and quality certification, and none of them can be ignored. As a leading domestic acoustic technology enterprise, RIBRI provides accurate solutions for users in different scenarios through two major series of directional and omnidirectional LRAD systems, full - chain customization services, and strict quality control. Whether it is emergency communication, safety prevention and control, or bird hazard management, users can follow the steps of "clarifying the scenario - screening parameters - customizing details - verifying quality" and combine the characteristics of RIBRI products to select the most suitable LRAD acoustic system, making acoustic technology truly a "sound shield" for safety protection.